Fall 2022

Engineering, Plastic Parts, Generative Design, Topology Optimization, 3D Printing, Prosthetic Design, Bill of Materials, Autodesk Fusion 360, CAD, Force Simulations

New Jersey (NJ)

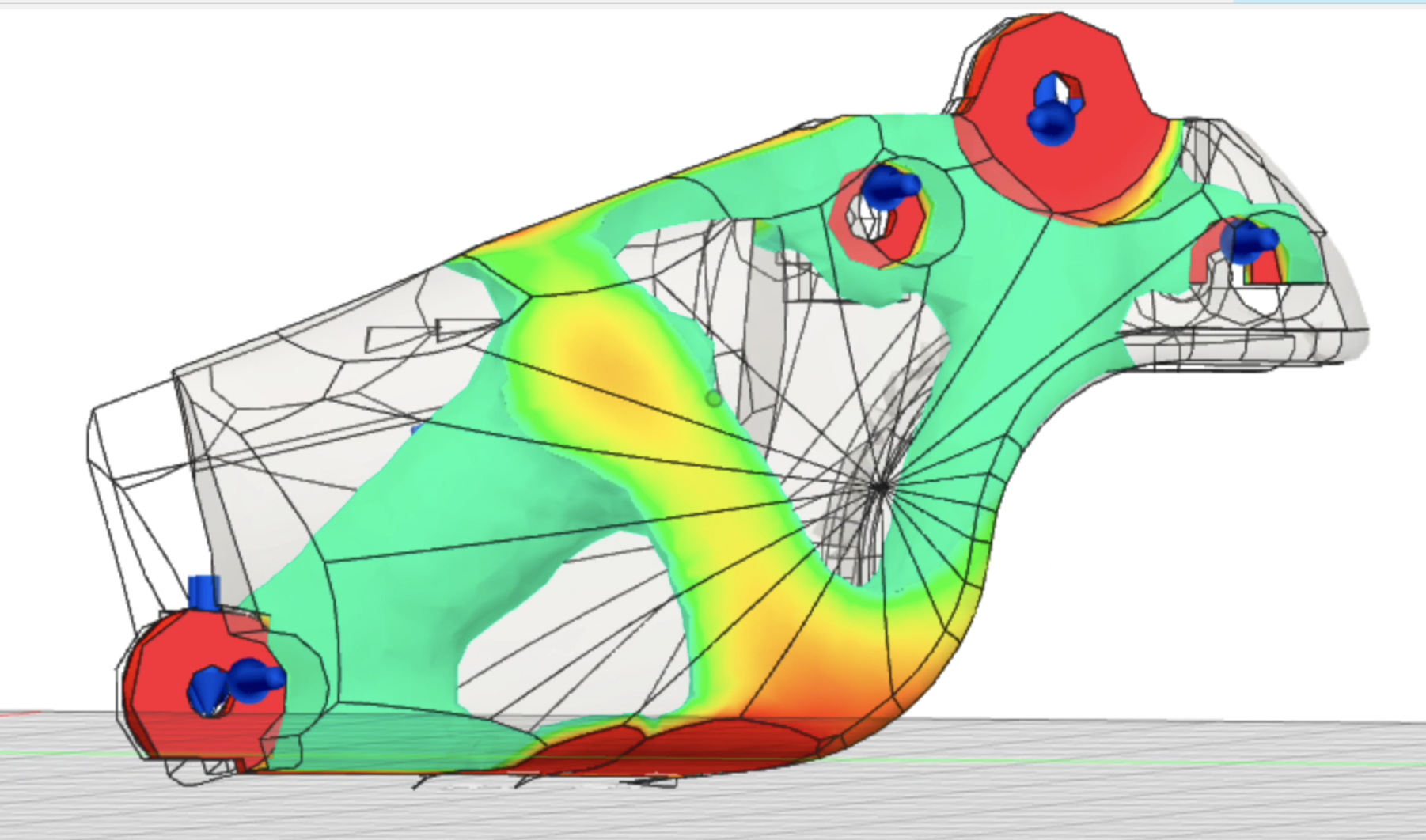

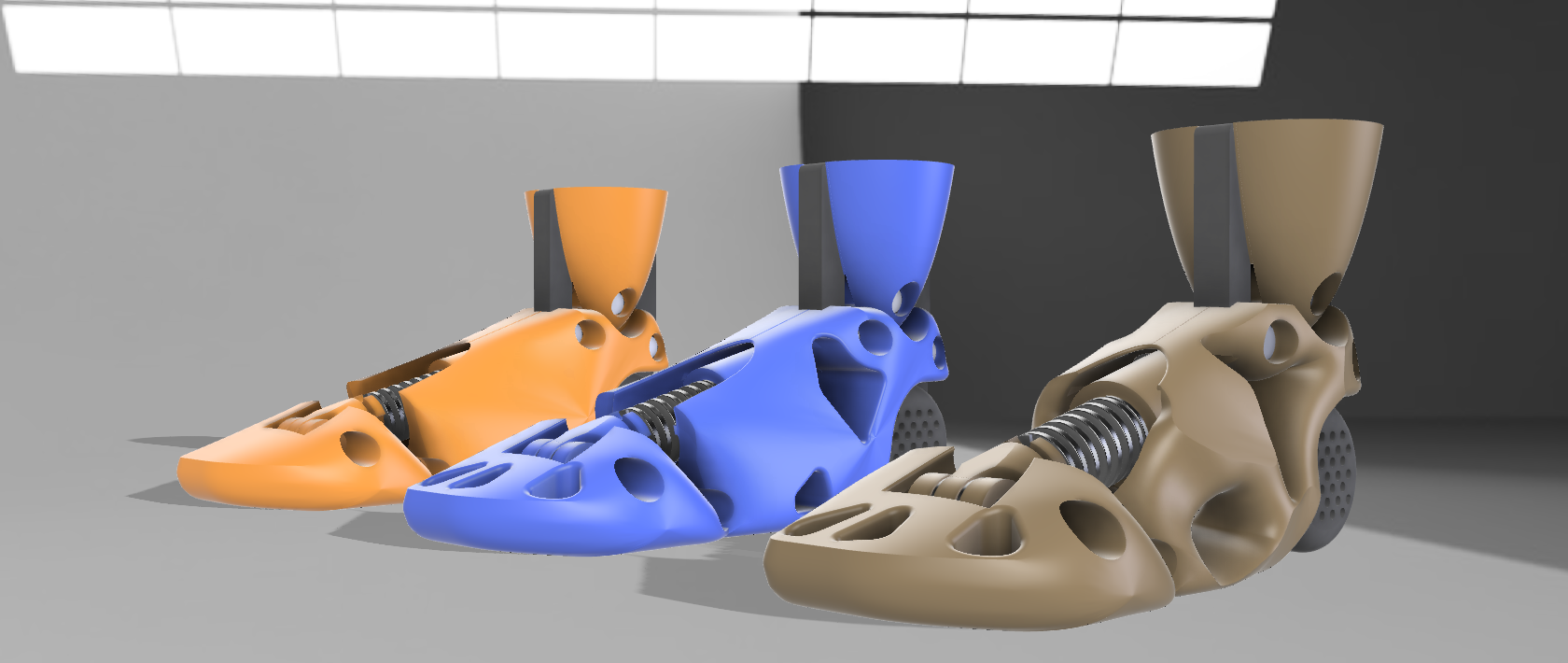

The static force/load simulations (SEE BELOW) at first proved the model highly susceptable to deformation/failure which allowed for several design revisions to strengthen joints and overall parts. Allon also experimented with generative design and topology optimization (SEE BELOW) to optimize the geometry of the plastic parts. This resulted in a cheaper, lighter, and potentially stronger assembly (simulation showed no loss in strength/performance). Three prosthetic foot designs were made with decreasing amounts of plastic. Real-world testing is needed to identify simulation shortcomings and test performance.

Allon then created a bill of materials detailing the sources, amounts, and costs of parts needed for assembly including all fasteners and filaments. Below is an animated exploded view of all parts in the final assembly. For an adult woman weighing <180 lbs. with a size 6.5 foot (US), the parts and polycarbonate filament cost an estimated $339.99 with the used material totaling around $173, not including a printer itself.

Topology Optimization of Mid-Foot half considering relevant and extreme loads (SEE VIDEO BELOW)

Topology Optimization of Mid-Foot half considering relevant and extreme loads (SEE VIDEO BELOW)

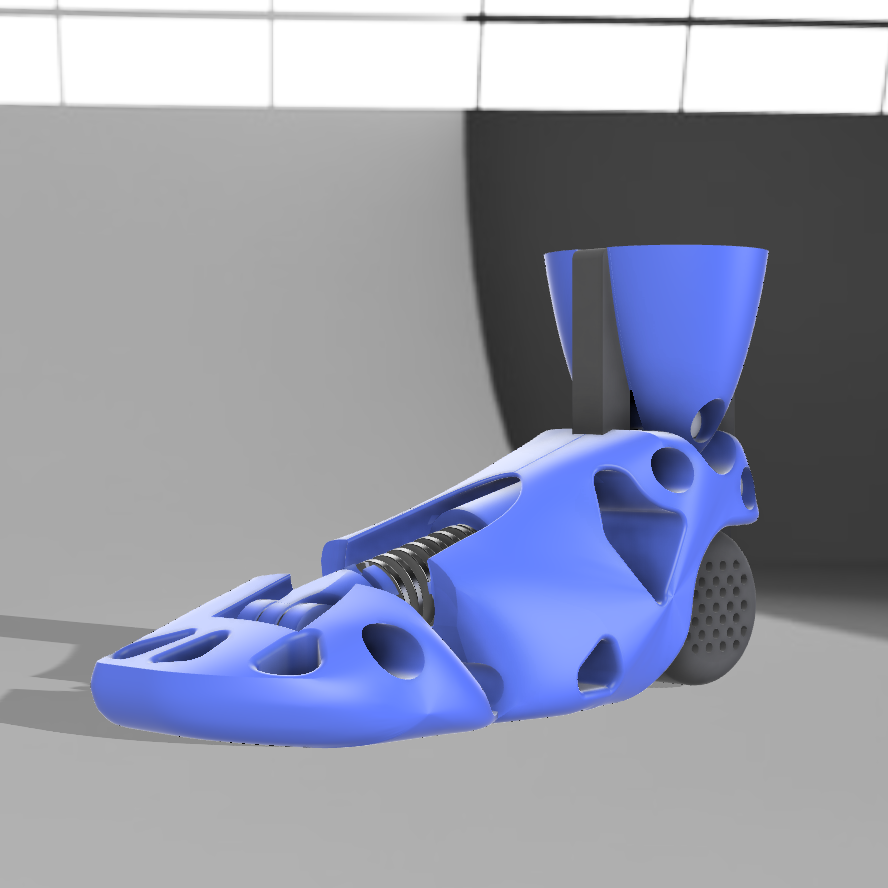

Final Render of Medium Plastic-Use Iteration

Final Render of Medium Plastic-Use Iteration

Render of the Three Designs with Decreasing Plastic-Use

Render of the Three Designs with Decreasing Plastic-Use

Render of the Three Designs with Decreasing Plastic-Use